I’m creating a board game that has custom 3d pieces. I’d like to test out my print before I send it to the game manufacturer and also want to make demo sets. They need a huge tooling fee before they’ll do samples. There are app. 10 designs and no bigger than 45mm.

I’m not sure as to whether I should buy a starter printer or would the learning curve be so big that I should just have a POD company do it. I know blender really well but have never printed anything from a file. I was going to make the file from blender for the company too. Any thoughts? I think my SO and I would use it for other things, probably, maybe, if it’s not so complicated that I give up on it.

Thanks for any advice on this, I don’t know what direction to point on this and I have a ton of work to do already.

Edit: You guys are awesome. I went from totally lost to ordering the Neptune 3 Pro and it should be here next week. Thanks for everything and I hope it goes pretty smoothly, I’ll keep you posted. Thanks again.

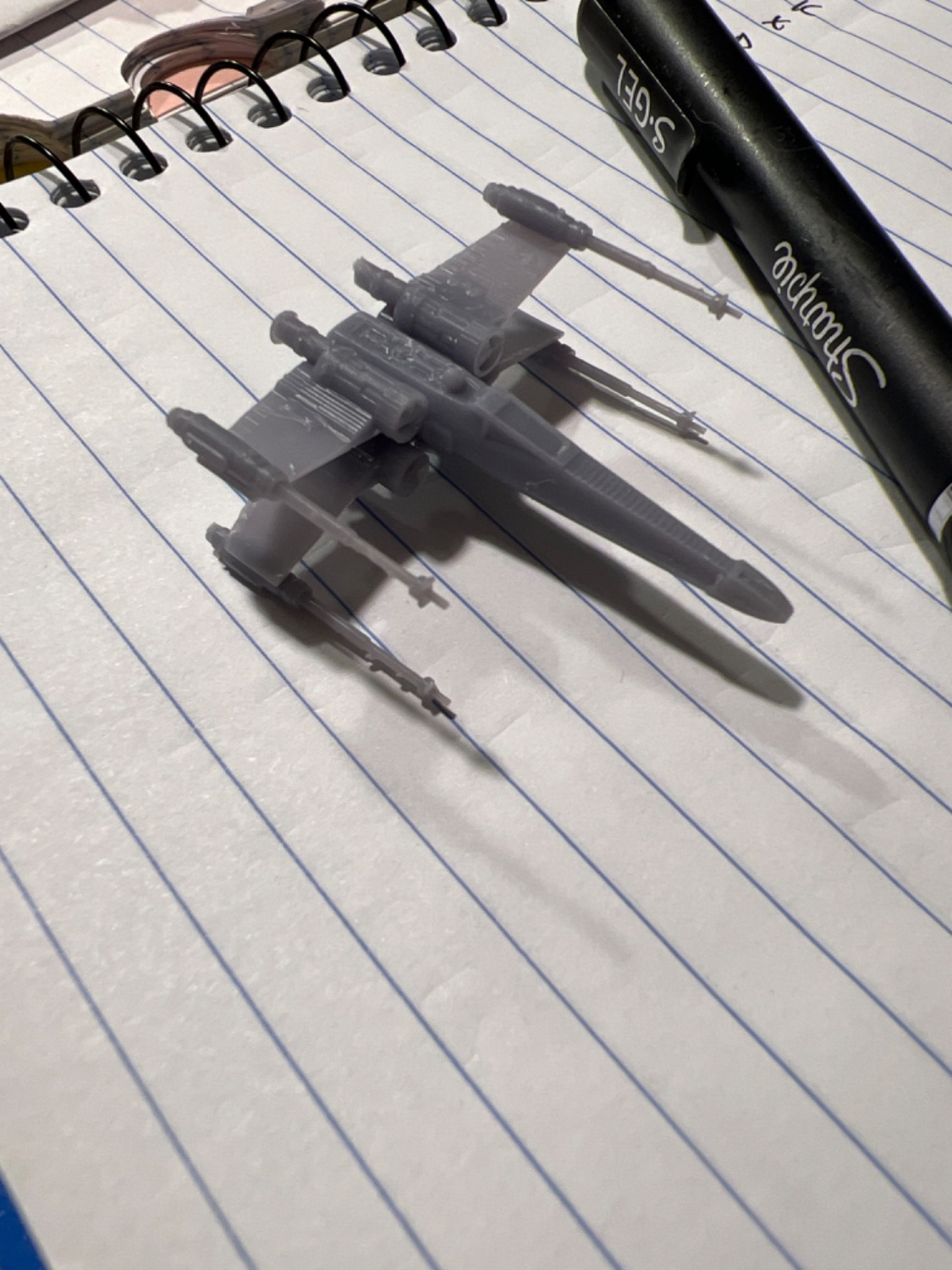

If your pieces are detailed I’d recommend a resin printer. I just got an anycubic photon mono x2 and I’m finding it excellent. I printed this x-wing a couple days ago.

I started 3d printing with resin printing too. But do you think it’s a good entry point for op’s this purpose?

Really depends on the models in my opinion. Small highly detailed models would do better in resin.

I started in FDM and then went to resin. For me resin is way easier. Far less fiddling with hardware.

The quote from the company said it was PVC, should I care about that? Great models btw, way more detail than I have.

They said they’d do the injection moulding in PVC? If so you’d be fine making prototypes/demos in resin.

Also, have you in to the game crafter to see if they can do what you need?

Yes, they saw most of my blender models and said that was the best choice. Not sure as to why, is that weird?

Also, have you in to the game crafter to see if they can do what you need?

I’m not sure of what that is, is that a community?

They’re a board game POD service https://www.thegamecrafter.com/

Wow, as I said, I’m new to this type of design. I just found a company someone recommended and haven’t really looked elsewhere. Thanks for that link.

“Makerspaces” exist for a reason.

You should be able to get access to a higher-quality 3d printer (or CNC mill, or Laser Cutter) from a typical makerspace. It’d be basically a club (often near universities) where people effectively pool their money together for collective ownership.

My local makerspace is at a community college. It requires a safety class before you can use the equipment, so there’s a few weeks of spinup time. The rules will be different wherever you are. In this case, my local State sponsored the funds for the 3d printer, but I still have to pay for resin costs and whatnot when using the printer.

Good software costs a ton of money too, and you might want to find a Makerspace just so that you can get access to the $4000+ class software that engineers use. Or at least the $1000+ software? Thinking like Rhino CAD, Autotools, or a few other professional tools.

Blender is more of a 3d graphics (think Toy Story movie) kind of workflow. It can do 3d designs but its not the original design.

I looked at the makerspaces in my area and all of their 3d printing classes are filled. I would have to pay by the half hour for them to do it but I have no idea how long each piece would take.

My local makerspace is at a community college.

I just checked, no dice.

Blender is more of a 3d graphics (think Toy Story movie) kind of workflow. It can do 3d designs but its not the original design.

I’m not sure I understand what you mean by that, I know AutoCAD, Revit, Blender and have used 3D Studio a long time ago, it uses the same basics of building in 3d. Do you mean the slicing software?

Edit: I appreciate the suggestions, I hope that didn’t text weird.

CAD software is better suited for precision designing. I don’t know if you would require that kind of presicion for board game parts. At least for early stages it may not be a requirement.

I for one still use blender for kinda presicion 3d models.

The models are already built, I made them awhile ago. Some of them have some issues with pieces being random and I wasn’t sure how clean I need to make the models for them to print well. This is one of the reasons I kind of want to get my own printer too, I don’t know how much I don’t know.

Edit: Sorry, I misunderstood what you were saying. Yes, Blender does great for detailed drawings as well as movies.

Blender has a ton of “movie” features, such as animation, keyframes, bones, etc. etc. Its almost entirely focused on movie-making. None of these features are useful to you, and in fact they’re harming your workflow. (They’re distracting items on the menu and manual)

Rhino, which is a freeform CAD program for industrial design has many more features. Not only is it $1000 however, but its focus on making artistic 3d printed models is obvious once you use such a program.

AutoCAD is more of an engineer’s tool. Its extremely precise but non-artistic in design. Its $4000 as well, but also the wrong tool for making a board game piece.

You’re using the wrong 3d program (Blender) to make your board game pieces. That’s all I’m saying. The people in the know would use a program like Rhino (or a comparable industrial design 3d to manufacturing tool). Blender can work, but its obvious that it doesn’t have the CAD or CAM features that a proper industrial tool would have.

Without a CAM-plugin package, are you even sure that your design can be 3d printed correctly? Have you thought about how the 3d printer nozzle (or CNC mill, or whatever you’re using) will create the end-product? Do you have holes in your design?

Do you have any overhangs that are unstable or unable to be printed?

https://www.3dprintingera.com/3d-printing-overhangs-and-bridges/

A tool like RhinoCAM-Mesh (ugggh, another $1000, but you get the gist of this hobby…) will automatically 3d print supports that will snap off so that whatever shape you wanted will be possible to be made.

https://mecsoft.com/products/rhinocam/rhinocammesh/

Just because you made it in Blender doesn’t mean its possible to 3d print. You need to double-check the “head” of the 3d printer, see if it ever collides with your design, check to see overhangs are set, etc. etc. Sometimes, its impossible and you have to go back to square-one and redesign the whole toy (or sculpture) in order for it to be 3d printed.

Tightly-integrated CAM (computer-aided manufacturing) tools check these things for you. If you’ve never thought about how the 3d printer head moves, or what angles are impossible to print, or etc. etc., then you haven’t finished your job. You want to get the CAM to double-check these things for you, and yeah its expensive but its all software these days.

So yeah, a tool like Rhino (lol $1000) plus RhinoCAM-Mesh (lol another $1000) to do this workflow. Now you can do this all manually yourself of course and “design your 3d game piece” for 3d printing (including thinking of temporary struts / braces you need to print-then-cut-out to make your designs successful). But that takes a bit more skill and manual effort, because Blender has no such CAM tools available (at least, that I’m aware of).

I’m a heavy parametric CAD user, so I’m not very knowledgeable on blender, but I do know a lot of people who use it for this sort of modeling. It does actually have some really good parametric CAD plugins for when you need mesh parts to work well with precise dimensions.

Blender has a ton of “movie” features, such as animation, keyframes, bones, etc. etc. Its almost entirely focused on movie-making.

I appreciate what you’re saying but I’m not sure you’ve used Blender lately. It does sculpting, 3d tech and all that, it gets very precise. It’s not as easy to use as AutoCAD and Revit to get precise, but you can do it. All of the architects and engineers I know and work with use AutoCad and Revit and it’s for creating details for arch & hvac drawings. The company I’m working with said they will adjust the file and have that built into the price for manufacturing. I just want to give them a clean file. Thanks though, I don’t think I need it for this, the company I’m working with knows what I’m giving them and seem fine. It’s one component of a huge puzzle.

It does sculpting, 3d tech and all that, it gets very precise

I’m not talking about sculpting. I’m talking about overhangs and other fundamental issues that 3d printers need to solve before the darn thing is printed.

I’m looking up Blender’s features, and it seems like there are features that can do this stuff (ex: https://docs.blender.org/manual/en/latest/addons/mesh/3d_print_toolbox.html), but even then…

Blender can be used to created meshes for 3D printing. Meshes exported from Blender are usually imported into a piece of software takes the mesh and “slices” it into paths that the 3D printer can execute. An example of such Slicer software is Cura.

Even in Blender’s manual, it seems like they’re suggesting you need a 2nd piece of software to do this job well.

The physical act of creating a 3d print needs to be thought of, especially in artistic designs. You will often create impossible shapes (most noticeably overhangs), especially if you’re ignorant to the whole 3d printing process. Having good software that detects these situations is… well… maybe not necessary. But it helps.

If you’ve never sent your (computer) sculptures through a CAM or thought about these issues before, I can guarantee you that you’ve accidentally made a wall too thin, or a overhang that’s impossible to print, or other such distortion that will 3d print poorly (or be impossible to 3d print).

The measurement of good software is the number of edge cases that it detects before you waste hours on a print job.

Each print job is a prototype. You gotta iterate. You 3d sculpt. Then you CAM-simulate to look for obvious errors. Then you 3d print. Then you figure out what went wrong and 3d sculpt again. Etc. etc.

The more issues the CAM-software detects before printing, the faster you iterate (ie: 3d sculpt. Find an issue in the CAM check. Return to 3d sculpt before printing to fix the issue). I have severe doubts that Blender (or even Blender + Cura, as recommended in this manual) covers as many issues as Rhino + RhinoCAM (as a random example of $1000+ software).

That’s… okay. I’m not saying you need to buy more expensive software. But what I’m saying is that what you’re losing out in terms of software is something YOU need to make up with experience. YOU need to learn about overhangs, or other such issues that can prevent a 3d print from becoming successful.

EDIT: Looks like you already ordered the printer. Well, you’ll learn soon enough one way or the other. Thinking about the print is easier than designing in the first place, but its still a process. Good luck with learning slicers + cura to get your Blender stuff to work!

Its not impossible, but don’t expect a success on your first print. And always be willing to go back to your Blender model and change it so that its physically possible to print. Iterate-iterate-iterate, that’s my ultimate advice to you. (And while good tools can quicken the iteration cycle, Blender is possible, just not ideal IMO).

Blender has great add-ons for 3dprinting too. And are you trying to advertise a software? There are shapes that are impossible to 3dprint, however overhangs are not one of them. You can use supports, you can reorient your design, you can use bridging…

Check with your local libraries! I work in a public library makerspace, we do this kind of stuff all the time. Most libraries do it either completely free or for the price of materials

Wait, I’m in Seattle, we have a great library and I never thought I should check there. I’ll look into there or the King County libraries. Thanks for that info.

Edit: Apparently we do not have a great library in that respect. No 3d printers, which is surprising tbh.

Awww that’s a shame! I’m honestly pretty surprised, my library isn’t even that big. Tell them to get their act together lol

I just found one out the king county has one but we already ordered the neptune 3 pro. We might check it out anyway to just see. Their classes are all filled for the near future as well.

It seems I’m too late to offer advice on your initial question, but I’m in the Elegoo family ane can say I’ve been enjoying my Neptune 3. There is a channel that you should check out on YouTube, guy goes by “The Feral Engineer”, he has done a ton of work on these printers and if you find his profile on Reddit he was insanely fast to message me back with a question I had for him.

Happy printing!

The Feral Engineer

Thank you, these look great. https://www.youtube.com/@Theferalengineer/videos

If you’re planning on doing more than one, then definitely it’s amazing and useful. If it’s just the one, then there are 3d printing services that have a decent turnaround and relatively reasonable prices. One benefit for really small runs is you don’t need to learn how to set up the printer, they’ll figure it out for you.

One thing to remember is that 3d printing manufacturing constraints are much different than injection molding manufacturing constraints.

Yes, we have lots of ideas, lol. I have no idea if we’ll follow through on them though. We’re thinking of using it for casting glass and other metals but we’ll see how these projects go.

One thing to remember is that 3d printing manufacturing constraints are much different than injection molding manufacturing constraints.

I think you’re talking about the undercuts and simple details, my representative said they built that into the price of them fixing that sort of thing. I just want to give them a clean file to work with that has the least for me to do. I also want to have some mock-ups to possibly give reviewers, so it’s okay if they look different. I really appreciate you mentioning that though, you might be referencing something I don’t know about.

I think they mean that because of the unique process that 3d printers use to create something, stuff that can be made easily on a 3d printer can’t be replicated through other manufacturing techniques, and vice versa. For example, I designed an earring that is 1 solid object, but made up of 3 separate moving pieces; like links of a chain that have no split in them. This would be an impossible task for any other kind of manufacturing process. It would be like making acar engine all at once, rather than having to make the individual parts and then assemble them afterward. You can have gaps and cavities in a print that you could never have in a cast or injection molded piece. But this method means that you also have to worry about things that you wouldn’t using more traditional manufacturing techniques.

I think I understand what you mean now, it’s the actual process.

This is what 3d printing really shines in. Churning out prototypes for minimum cost.

If you’re already familiar with blender, you would only need to learn how to use a slicer, which is not that hard in comparison. Just import the model and fiddle around with print settings if needed.

I came into 3d printing as a complete noob, and most of my time has been spent learning to do modeling in blender/cad. Slicing and printing itself is simple in comparison. Resin might be more involved.

That’s super great to hear that the slicing should go easy. I’ve been looking at YouTube and I downloaded Prusa, it looks like if I follow the directions and don’t change much, it should be fine. I appreciate the encouragement because I am a total noob at this part for sure.

3D printing has become really accessible over the past few years. Many affordable entry level printers come with automatic bed leveling and direct drive extruders, which previously only came on more expensive printers. IMO, it sounds like your use case is perfect for 3D Printing. There’s a variety of great entry level printers you can pickup right now for fairly cheap. I don’t have experience with them myself, but the Elegoo Neptune 3 or 4 seem to be well regarded for their price point. As far as getting started, Thomas Sanladerer has a great intro to 3DP that can get your started on the concepts. It’s not hard to pickup. https://youtube.com/playlist?list=PLDJMid0lOOYnkcFhz6rfQ6Uj8x7meNJJx

Here is an alternative Piped link(s): https://piped.video/playlist?list=PLDJMid0lOOYnkcFhz6rfQ6Uj8x7meNJJx

Piped is a privacy-respecting open-source alternative frontend to YouTube.

I’m open-source, check me out at GitHub.

The youtube link is priceless, I looked for info on how to start but there was just too much with so many other things going on. I really appreciate that link. I read somewhere about the self-leveling, that sounds like a must have that I’ll try to remember not to let go by the wayside.

For figures, and especially testing things that will compare to injection molding, going FDM is a really bad idea. It’s superior for engineering parts and rapid prototyping in basically all cases, but is has terrible dimensional accuracy by comparison, and it has a ton of trouble with thin features and overhanging shapes. This is mainly because the nozzle width is orders of magnitude wider than the pixels on a resin printer, so the slicer has to get very creative with dimensions to make complex models work at all. I am a huge FDM enthusiast, but this really isn’t the right place for it.

I’m pretty sure I get what you’re saying. They have the pricing built into the quote for fixing my file, he’s already looked at what it’s going to look like and thought they would need to change a few things. I’m totally cool with that, I’m just trying to have a working file to give them and test a few things. Also, I’d like to have a mock-up to send to reviewers. Thanks for trying to warn me though, I understand what you’re saying.

What things are you testing? If it’s really nothing to do with the way it looks cosmetically, then you will be fine with FDM. But for mockups for reviewers, you may want to just order them SLA’d from JLCPCB. I got a part made by them and the quality was phenomenal and it was super cheap and fast. It’s slower than printing it yourself, but the quality is worlds better and you would have to order hundreds and hundreds before it costs more than buying a printer.

I’m just testing my file for the most part. I’d also like to make a few mock-ups for testing and reviewers for the crowd sourcing campaign. I’ve already ordered the printer and I should get it in a couple of days. Thanks for the source anyway, it looks like a nice place to get stuff printed.

I suppose as you are a builder ( a game designer it’s most probably is) it would be a great help to have a 3d printer at hand.

Bambu printers,

Elegoo neptune 4 series, Prusa mk3/4s are great ones to start with.This is my first game with pieces like that, I probably should have mentioned that. Thanks for the suggestions on models, that Elegoo Neptune 4 series seems to be perfect in price range too since I think a POD would have cost about that much.

In fact Neptune 3 pro can be cheaper option. It would be slower to print but still create perfect prints. I do print with A Neptune 3 plus, a larger version of the 3 pro, and quite happy with it.

We were just looking at the differences. I wonder if we should spend the extra $100 to get the 4 pro in a couple of weeks or get the 3 pro while we’re still excited.

Depends on your patience. If you are very impatient go for the 4 pro as it’s built for faster printing. Otherwise they are very similar for print quality.

4 pro wasn’t available at all in the US, so we ordered the 3 pro. Thanks for all of the advice.

@PeleSpirit 3D printing is fun but it can be a time sink. Consider how much done you can invest in this. If you want to push on with other things then POD may be best. If you want to have it as a tool in your bag, then buy one for sure.

One thing I would say about resin printers is they can’t be left for long periods and are best cleaned and packed away if you aren’t using them.

3D printing is fun but it can be a time sink.

Ruh roh, we’ll see how it goes since I ordered the Neptune 3 pro. Thanks for the heads up though.

@PeleSpirit good luck. I didn’t regret it. Been lots of fun!

Thanks again, you all ave really been so helpful.

So you can get an Ender or similar printer for $100-200 and it would mostly work out of the box, but there is often a huge amount of troubleshooting that follows. I got a 3D printer originally to try to earn extra revenue but never ended up selling anything because the hobby took over for me. I spent hours learning how it works and hundreds replacing parts (trying to perfect my machine, not at all necessary). It’s a bit of an investment of time and money but you may find that you end up enjoying it and using it beyond the scope of your current project. It’s definitely something that takes a lot of commitment to learn unless you have a lot of money you’re willing to invest towards a more no-issue printer like a Prusa.

It looks like there are a ton of makerspaces in Seattle. If you have the time, you can actually often volunteer to use the machines for free. And it would give you the ability to use other machines there, like laser cutters. I actually also volunteer about a couple hours north of you at the bham makerspace. If you happen to be in the area and want help printing stuff – or you decide to get a printer and you want help learning how to do it, you should hit me up! I’m super passionate about it and I would be happy to give you advice or help out. :)

I wish I had the time to volunteer, but that’s a great idea if things start to slow down. I just ordered the Neptune pro 3 as a starter for this project so we’ll see how the ease of use goes. I tried all the maker spaces I could find locally and they were either all booked up so you could use the space or they charged $25/half hour and I have no idea how long everything would take. I will definitely hit you up when we get a break from all the stuff we’re doing, that’s a gorgeous drive. Thanks for the offer of help, I really hope I don’t need it, lol.

Hey sounds great! You’ve made a good choice. If/when you have any issues pop up that you need a quick solution to, I’ll be around :)

Thank you, I’m kind of overwhelmed with how awesome you guys are in here. I’m from Seattle and we actually have the Seattle Freeze as a thing so I’m not used to it, lol. Well I guess you already know that, but others don’t.

Shapeways.com and printathing.com

Usually can upload a file and they will print and ship to you

Never used anything like that, but I recommend it anyway. Learning about printing and modeling for printing is fun but takes a lot of time. Then you make a perfect model for 3D printer which cant be moulded…

Id go stright to design for moulding and pay someone for 3D print on resin printer. If model is not suitable for printing you can add supports or just split it in 2 parts and glue them afterwards.

But if you need a new hoby, 3D printing is awesome and affordable nowdays. It can help with your board game design as well. You can even consider 3D printing as main techology

I’ve heard of shapeways but not printathing, thanks.